Products

-

Film Faced Birch Plywood – Phenolic Faced Birch Plywood

- Name: Film Faced Birch Plywood – Phenolic Faced Birch Plywood

- Loading Quantity: 20’GP-8pallets/20CBM, 40’HQ-18pallets/40CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: Brown/Black/Red Film, Dynea Film, MDO, HDO

- Core: Birch Veneer

- Size: 1220x2440mmcustom

- Thickness: 9-30mm/custom

- Glue: Phenolic-WBP/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 680-700KGS/CBM

- Moisture Content: <12%

-

Finger Joint Strip Core Film Faced Plywood Board

- Oversized Film Faced Plywood Board

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: Brown/Black/Red Film, Dynea Film, MDO, HDO

- Core: Poplar/Eucalyptus/Combi

- Size: 2000x5000mm/1500x3000mm/custom

- Thickness:18-30mm/custom

- Glue:MR/Melamine/Phenolic-WBP/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

Formica Plastic Laminate Sheets

- HPL Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: HPL/custom

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–18mm/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

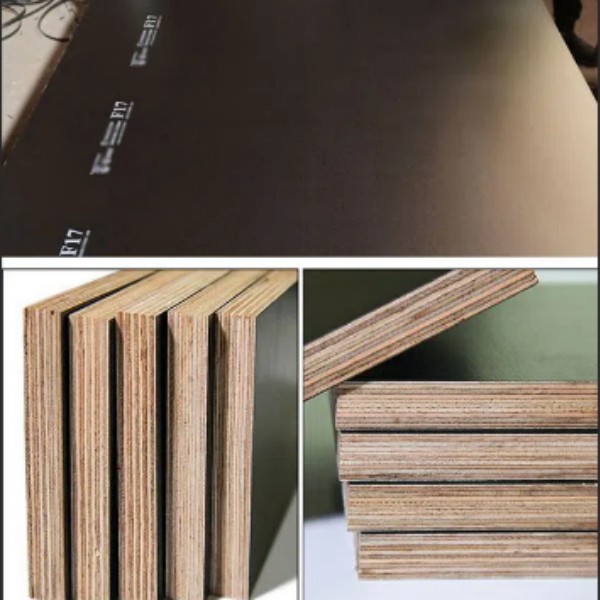

FORMPLY F17 1800 X 1200 X 17MM FORMWORK PLYWOOD

FORMPLY F17 1800 X 1200 X 17MM PLYWOOD

F17 Formply, 17mm Formply 1200*1800mm

Size: 1220*1800mm, 1200*2400mm

Thickness: 17mm

Core material: Hardwood, Birch, Pine, etc

Glue: Phenolic glue(72 hours in boiling water)

Face/Back: Dynea Film, Black/Brown Film, Class 2

Moisture Content: 6-10%

Application: Concrete Formwork, Construction, Wagon building, etc

-

Formwork LVL 95*65MM

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives . Formwork LVL beams are designed for the high load-bearing and corrosive environment of the concrete formwork industry and are used as formwork bearers, joists, soldiers and walers. The slow growing plantation timber veneers make e-form one of the highest load bearing formwork LVL beams in Australia. A high wax loading in the moisture-repellent coating improves its dimensional stability and extends its life and cost effectiveness.

-

Framing LVL Beam

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives . It is typically used for headers, beams, rimboard, and edge-forming material. LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter, and more uniform. Due to its composite nature, it is much less likely than conventional lumber to warp, twist, bow, or shrink. LVL is a type of structural composite lumber, comparable to glued laminated timber (glulam) but with a higher allowable stress.

-

Full Pine LVL Used for Construction Cement Damper

- Full Pine LVL Used for Construction Cement Damper

- Loading Quantity: 40’HQ-24pallets/50CBM

- MOQ: 1X40’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Radiata Pine

- Thickness: 36mm/45mm/custom

- Glue: Phenolic-WBP/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 560KGS/CBM

- Moisture Content: <12%

-

Glossy UV Birch Plywood

Glossy UV plywood finish featuring a clear, durable top coating to add toughness, resisting to scrapes and chip. UV coating is basically a compound that is applied to wet wood and then instantly dried by ultraviolet light. Several different types of compounds are used to coat wood.

- UV Coated Plywood

- Loading Quantity: 20’GP-8pallets/20CBM, 40’HQ-18pallets/40CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: UV Lacquer

- Core: Birch /Customs

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:5–30mm/custom

- Glue:Phenolic/E0/E1/E2/Custom

-

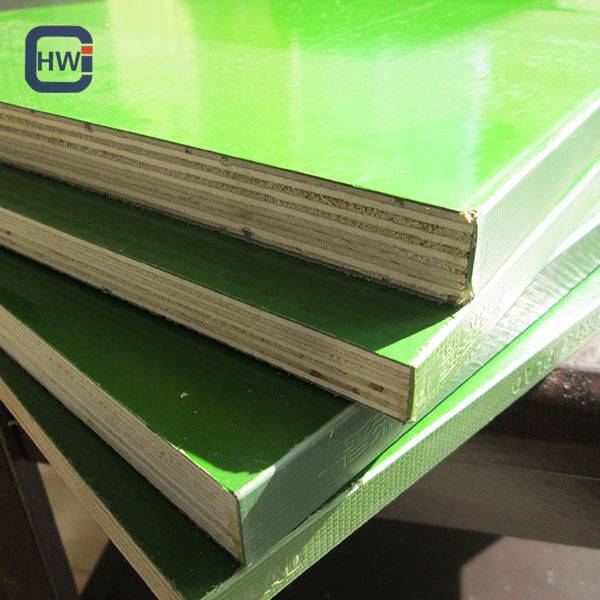

Green PP Plastic Faced Plywood

- Water and Moisture Resistance: The polypropylene coating provides excellent resistance to water and moisture, making this plywood ideal for outdoor, marine, or humid environment applications, where traditional wood would degrade.

- Durability and Wear Resistance: The plastic face is highly resistant to wear, tear, and abrasion, ensuring a longer lifespan and maintaining its appearance over time, even under heavy use.

- Chemical Resistance: This plywood is resistant to a range of chemicals, making it suitable for laboratory, industrial, or agricultural applications where chemical exposure is a concern.

- Easy Maintenance and Hygiene: The smooth surface of the PP coating is easy to clean and sanitize, which is beneficial for applications in healthcare, food service, or any area where hygiene is a priority.

- Versatility in Applications: Despite its specialized coating, PP plastic-faced plywood retains the workability of traditional plywood, allowing it to be cut, drilled, and shaped easily for a variety of uses, from construction and automotive to furniture making.

-

Grid Meshed Anti-slip Plywood

Anti-Slip Film Faced Plywood is an Engineered Plywood with high quality and applicability, Coated With Brown, Black, Red Or Gray Film. The patterned phenolic film surface is semi-glossy, hard and resistant to impact and abrasion. Its widely used for House Building, Road Construction, Concrete Project, Scaffolding, Bridge Beams, and all kind of Flooring ( In The Transportation Industry, The Heavy Duty Pattern Face Gives Superlative Slip Resistance).

-

Grid Meshed Anti-slip Plywood For Sale

Anti-Slip Film Faced Plywood is an Engineered Plywood with high quality and applicability, Coated With Brown, Black, Red Or Gray Film. The patterned phenolic film surface is semi-glossy, hard and resistant to impact and abrasion. Its widely used for House Building, Road Construction, Concrete Project, Scaffolding, Bridge Beams, and all kind of Flooring ( In The Transportation Industry, The Heavy Duty Pattern Face Gives Superlative Slip Resistance).

-

Hexagonal Anti-slip Film Faced Plywood

- Name: Anti-slip Film Faced Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/40CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: Domestic Black or Brown film, Dynea film

- Core: Russian Birch Ply / Baltic Birch Ply / Eucalyptus Ply / Poplar Ply / Combi Ply

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:9-30mm/custom

- Glue:MR/Melamine/Phenolic-WBP/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 680-700KGS/CBM

- Moisture Content: <12%