HW Engineered Wood Veneer, EV, Sliced Veneer

A sliced veneer is a type of thin wood veneer that is produced by slicing a log into thin sheets using a rotary cutter. This process produces a continuous sheet of veneer with a uniform thickness and a consistent grain pattern. Sliced veneer is often used for decorative purposes, such as in furniture-making or in the production of paneling or cabinetry.

There are several types of sliced veneer, including rotary-cut veneer, flat-cut veneer, quarter-cut veneer, and rift-cut veneer. Each type of sliced veneer is produced by cutting the log in a different way, resulting in a unique grain pattern and appearance.

Sliced veneer is typically sold in large sheets or rolls and is available in a wide variety of wood species and finishes. It is a popular choice for those looking to add a natural, high-quality finish to their woodworking projects.

Parameters

| VENEER TYPE | THICKNESS | SIZE | LOADING | DELIVERY | |||

| OKOUME | 0.2/0.25/0.3/0.4/0.55/0.6/0.7MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PENCIL CEDAR | 0.2/0.25/0.3/0.4/0.45MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PLB | 0.25/0.3MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| BINTANGOR | 0.2/0.25/0.3/0.4/0.45/0.5MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PINE | 0.5/0.6/0.7/0.8MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| EV | 0.2-1.5MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| Grade | A, B, C, D | ||||||

| Specification | Grade A: No discolor, No fiber, No hole, No splits Grade B: Slight discolor, small crack, No hole, No fiber Grade C: Medium discolor, Slight pin, bean hole, Light fiber Grade D: Discolor, splits, egg-size holes no more than 3 |

||||||

|

Moisture |

8-12% | ||||||

| Lead time | 10-25days after the deposit received | ||||||

| Shipping terms: | FOB, CNF, CIF | ||||||

| Package: | Standard Seaworthy packing | ||||||

| Inner Packing: The pallet is wrapped with a 0.20mm plastic paper | |||||||

| Outer Packing: The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||||

| Also, 6*3 metal belt | |||||||

| products samples | For free samples, need to pay the delivery fees of 1-2 days for ready samples, customized for 15 days. |

| After-sales services | After receiving goods, if any quality problem, take photos and send them to us. Then provide you free boards to replace in the next order after checking. |

| Product customization | no strict requirement about the size, but the tailored way should be basic on the basic material’ size. |

Sliced Veneer Feature

1. Thinness: Sliced veneer is very thin, usually ranging from 0.5mm to 3mm in thickness, which makes it easy to handle and apply to a variety of surfaces.

2. Consistency: Sliced veneer is produced using a rotary cutter, which results in a continuous sheet of veneer with a consistent thickness and grain pattern.

3. Wide range of wood species: Sliced veneer is available in a wide range of wood species, including both domestic and exotic hardwoods.

4. Flexibility: Sliced veneer is flexible and can be easily bent or curved to fit the contours of a surface, making it ideal for use in furniture-making and other woodworking projects.

5. Cost-effective: Sliced veneer is often less expensive than solid wood, making it an attractive option for those on a budget.

6. Environmentally friendly: Sliced veneer is a sustainable and eco-friendly option, as it allows for more efficient use of wood resources and reduces waste.

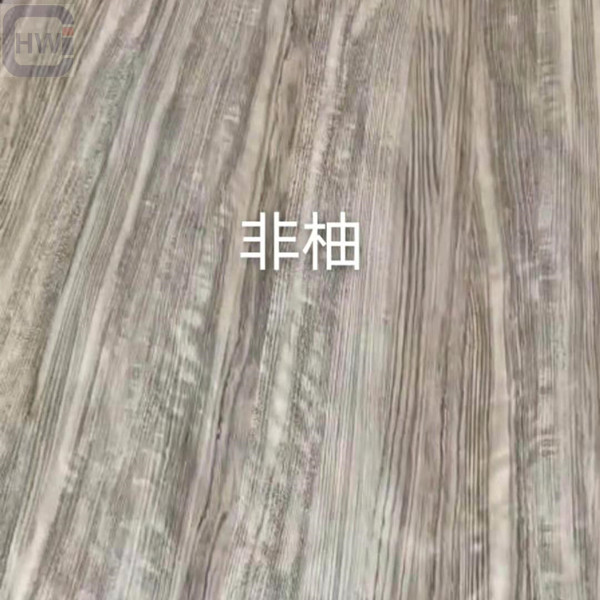

Product Show

About the company

1. HW Group is your plywood manufacturer in China which can produce customized products with professional technology.

2. OUR MISSION is endless innovation, providing customers with high-quality products and services.

3. CERTIFICATION: CE, ISO, FSC, ASNZS, CARB/EPA

4. MAIN PRODUCTS: Thin Plywood, Furniture Grade plywood, Commercial Plywood, Film faced plywood, Fancy Plywood, LVL, and so on

5. CAPACITY Factory was established in 2002, located in Pizhou City, Jiangsu Province, covering

30,000 square meters, has 200 workers with 50.000CBM/year capacity, exports 1000 containers per year

6. ADVANTAGE 1)Professionalmanufacture technology and strong global resource meet your variety of demands. 2)Perfect and independent inspection system 3)Owner equips very fluent spoken English will further promote strategic partnership building between the two sides. 4)Honest and trustworthy. Responsible until after-sales.

7. MAIN MARKET Europe, America, Australia, Middle East, Asia, and Africa.

8. SERVICE HW has a sales team, docs team, quality inspection team, and logistics team

Mark:

EV veneers also named reconstituted veneers laminated plywood,

is one of our best-selling furniture grade of boards. We usually

recommend customers for the Poplar core, combi core, and Eucalyptus

Core strives for high-end quality products. surface species can

be a lot of different series, like oak, teak, poplar, cherry, and so on,

and we are working with several big mills of recon veneers producer

for multichoice. and this product is ideal for the furniture grade and

countertop material first choice

FAQ

Q: What is the difference between sliced veneer and peeled veneer?

A: Sliced veneer is produced by slicing a log into thin sheets using a rotary cutter, while peeled veneer is produced by peeling the log into thin sheets using a lathe. Sliced veneer has a more consistent grain pattern, while peeled veneer has a more irregular pattern.

Q: How is sliced veneer used?

A: Sliced veneer is used for decorative purposes, such as in furniture-making, cabinetry, and paneling. It is also used in the production of musical instruments, such as guitars and pianos.

Q: Can sliced veneer be stained or painted?

A: Yes, a sliced veneer can be stained or painted just like solid wood. However, it is important to sand the veneer lightly before applying any finishes to ensure that the surface is smooth and free of imperfections.

Q: How is sliced veneer produced?

A: Sliced veneer is produced by first selecting a log of wood and then slicing it into thin sheets using a rotary cutter. The sheets are then dried and sanded to the desired thickness and smoothness.

Q: Is sliced veneer environmentally friendly?

A: Yes, sliced veneer is a sustainable and eco-friendly option, as it allows for more efficient use of wood resources and reduces waste.