Lightweight Furniture Plywood Panels – HPL Laminated Plywood

Product Details

HPL (High Pressure Laminates) is a kind of high-tech green environmental decorative material. It has excellent properties such as impact resistance, UV resistance, weathering resistance, abrasion resistance, scratch resistance, chemical corrosion resistance, easy cleaning and fire prevention, and antistatic and moisture-proof.

Made up of a wear-resistant overlay, decorative sheet, and impact-resistant kraft, HW® High-Pressure Laminate (HPL) offers long-lasting beauty, function, and performance.

A high-performing, durable engineered surface used for a variety of vertical and horizontal applications, HW’s HPL also offers a broad range of attractive patterns and texture possibilities.

The value of HPL is often underestimated. The paragon of engineered laminates, HW’s HPL is an economical choice with lower minimum order quantities, easier maintenance, and better lead times than comparable surfaces.

Ideal for countertops, cabinets, fixtures, shelves, architectural doors, walls, and more, HW® HPL is also available in a number of specialty products, Writable Surfaces, and more.

Lightweight Furniture Plywood Panels – Hpl Laminated Plywood Feature

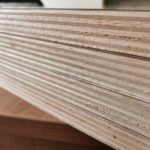

1. Lightweight: The plywood core of HPL laminated plywood is lightweight, making it easy to handle and transport.

2. Durable: The HPL layer on both sides of the plywood provides excellent durability and resistance to impact, heat, and chemicals.

3. Scratch-resistant: The hard-wearing HPL layer is also scratch-resistant, making it ideal for high-traffic areas and furniture pieces that are frequently used.

4. Moisture-resistant: HPL laminated plywood is highly resistant to moisture and can be used in areas with high humidity or moisture, such as kitchens and bathrooms.

5. Stain-resistant: The HPL layer is also highly resistant to stains, making it easy to clean and maintain.

6. Bacteria-resistant: HPL laminated plywood has antibacterial properties, making it a popular choice for healthcare and educational settings where cleanliness is essential.

7. Versatile: HPL laminated plywood can be used for a wide range of applications, including cabinets, shelves, wall panels, and furniture pieces.

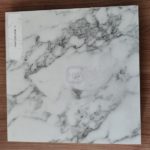

8. Aesthetic appeal: HPL laminated plywood comes in a range of colors and patterns, allowing designers to create unique and visually appealing furniture pieces and interiors.

Basic Parameters

| HPL Thickness: | 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1.0mm; |

| HPL Color: | Solid color; wood grain; |

| HPL Finishing: | Matt & super matt, glossy & high glossy, texture, embossment |

| Plywood Thickness: | 5mm to 30mm |

| Thickness Tolerance: | <6mm, +/-0.2mm ~ +/-0.3mm;>6mm, +/-0.3mm ~ +/-0.5mm; |

| Plywood Dimensions: | 1220X2440mm; 1250X2500mm; customized size; |

| Core Board: | Lightweight Plywood ( poplar core, combi core, hardwood core, birch core, Blockboard, MDF, Particleboard; ) |

| Glue: | E2/E1/E0/CARB/WBP Melamine/WBP Phenolic |

| Formaldehyde Release: | E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L, |

Technical Parameters

| Moisture Content | 8%~14% | |

| Modulus of Elasticity | ≥2500Mpa | |

| Static Bending Strength | ≥22Mpa | |

| Surface Bonding Strength | ≥1.20 Mpa | |

| Internal Bonding Strength | ≥0.55 Mpa | |

| Screw Holding Ability | Face | ≥1300N |

| Edge | ≥800N | |

Surface Species

Delivery Instructions

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization

Application

1. Furniture: HPL laminated plywood is commonly used in the furniture industry to create lightweight and durable panels for cabinets, shelves, tables, chairs, and other furniture pieces.

2. Wall paneling: HPL laminated plywood can be used to create decorative and functional wall paneling for commercial and residential interiors.

3. Retail displays: HPL laminated plywood can be used to create attractive and durable retail displays that can withstand heavy use.

4. Healthcare and educational settings: HPL laminated plywood’s antibacterial properties make it a popular choice for healthcare and educational settings where cleanliness is essential.

5. RV and camper van interiors: HPL laminated plywood’s lightweight and durable properties make it an ideal material for creating interiors for recreational vehicles and camper vans.

6. Exhibition booths: HPL laminated plywood can be used to create exhibition booths that are both lightweight and visually appealing.

7. Shopfitting: HPL laminated plywood can be used for shopfitting applications such as displays, shelving, and partitions.

HPL is more than just a surface. It is a modern, highly attractive, and multifunctional surface material. The outstanding product and environmental features turn it into a material flexible in application, which is head and shoulders above other surface materials and is used in nearly all areas of everyday life – such as kitchen, office, and living room furnishing, bathrooms, interior finishes, wall coverings, construction of retail as well as trade fair units and vehicle manufacture. And new application areas are waiting to be explored.

HPL

HPL is more than just a surface. It is a modern, highly attractive, and multifunctional surface material. The outstanding product and environmental features turn it into a material flexible in application, which is head and shoulders above other surface materials and is used in nearly all areas of everyday life – such as kitchen, office, and living room furnishing, bathrooms, interior finishes, wall coverings, construction of retail as well as trade fair units and vehicle manufacture. And new application areas are waiting to be explored.

impact resistant / stoßfest

FAQ

Q: What is HPL laminated plywood used for?

A: HPL laminated plywood is commonly used in the furniture industry to create lightweight and durable panels for cabinets, shelves, and other furniture pieces. It is also used in commercial settings such as hospitals, laboratories, and schools due to its resistance to moisture, stains, and bacteria.

Q: What are the benefits of HPL laminated plywood?

A: HPL laminated plywood is lightweight, durable, scratch-resistant, moisture-resistant, stain-resistant, bacteria-resistant, versatile, and has aesthetic appeal.

Q: What types of wood are used for the core of HPL laminated plywood?

A: The core of HPL laminated plywood can be made from various types of wood, such as poplar, birch, or eucalyptus.

Q: Is HPL laminated plywood environmentally friendly?

A: HPL laminated plywood is made using sustainable and renewable materials, such as wood and paper. Additionally, the production process uses less energy and water than other materials like plastic or steel. However, it is important to choose HPL laminated plywood that has been certified by organizations like the Forest Stewardship Council (FSC) to ensure that it comes from responsibly managed forests.

Q: Can HPL laminated plywood be painted or stained?

A: HPL laminated plywood cannot be painted or stained since the HPL layer is already a finished surface. However, it can be easily cleaned with soap and water or mild cleaning solutions.