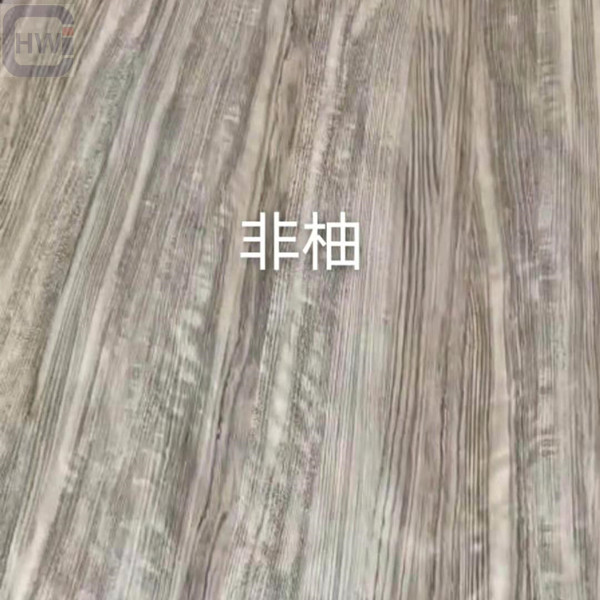

HW Sliced African Teak Veneer

African teak is a hardwood species that is commonly used in the production of veneers. Veneers are thin sheets of wood that are sliced from a log and used to cover furniture, cabinetry, and other surfaces.

Sliced African teak veneer is produced by slicing a log of African teak into very thin sheets using a slicing machine. The resulting veneers are then graded based on their quality, with the highest quality veneers being used for high-end furniture and cabinetry.

African teak veneer is known for its durability, resistance to moisture and decay, and beautiful grain patterns. It is also relatively easy to work with, making it a popular choice for both professional woodworkers and DIY enthusiasts.

When purchasing sliced African teak veneer, it is important to consider factors such as the thickness of the veneer, the quality of the wood, and the intended use of the veneer. It is also important to work with a reputable supplier to ensure that you are getting a high-quality product that will meet your needs.

HW Sliced African Teak Veneer Feature

1. Durability: African teak is a hardwood species known for its durability and resistance to decay, making it an excellent choice for veneers that will be exposed to moisture and wear.

2. Beautiful grain patterns: African teak has a distinctive grain pattern that is prized for its beauty and uniqueness. The grain patterns can vary from straight to wavy or even interlocked, giving it a rich and interesting look.

3. Easy to work with: African teak veneer is relatively easy to work with, making it a popular choice for both professional woodworkers and DIY enthusiasts. It can be easily cut, sanded, and finished to create a polished and professional look.

4. Available in different thicknesses: Sliced African teak veneer is available in different thicknesses, allowing it to be used for various applications, from covering large surfaces to wrapping around curves and corners.

5. Sustainable: African teak is sourced from responsibly managed forests, making it a sustainable choice for those who are concerned about the environment.

Parameters

| VENEER TYPE | THICKNESS | SIZE | LOADING | DELIVERY | |||

| OKOUME | 0.2/0.25/0.3/0.4/0.55/0.6/0.7MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PENCIL CEDAR | 0.2/0.25/0.3/0.4/0.45MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PLB | 0.25/0.3MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| BINTANGOR | 0.2/0.25/0.3/0.4/0.45/0.5MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PINE | 0.5/0.6/0.7/0.8MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| EV | 0.2-1.5MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| Grade | A, B, C, D | ||||||

| Specification | Grade A: No discolor, No fiber, No hole, No splits Grade B: Slight discolor, small crack, No hole, No fiber Grade C: Medium discolor, Slight pin, bean hole, Light fiber Grade D: Discolor, splits, egg-size holes no more than 3 |

||||||

|

Moisture |

8-12% | ||||||

| Lead time | 10-25days after the deposit received | ||||||

| Shipping terms: | FOB, CNF, CIF | ||||||

| Package: | Standard Seaworthy packing | ||||||

| Inner Packing: The pallet is wrapped with a 0.20mm plastic paper | |||||||

| Outer Packing: The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||||

| Also, 6*3 metal belt | |||||||

| products samples | For free samples, need to pay the delivery fees by 1-2 days for ready samples, customized for 15 days. |

| After-sales services | After receiving goods, if any quality problem, take photos and send them to us. Then provide you free boards to replace in the next order after checking. |

| Product customization | no strict requirement about the size, but the tailored way should be basic on the basic material’ size. |

Product Show

About the company

1. HW Group is your plywood manufacturer in China which can produce customized products with professional technology.

2. OUR MISSION is endless innovation, providing customers with high-quality products and services.

3. CERTIFICATION: CE, ISO, FSC, ASNZS, CARB/EPA

4. MAIN PRODUCTS: Thin Plywood, Furniture Grade plywood, Commercial Plywood, Film faced plywood, Fancy Plywood, LVL, and so on

5. CAPACITY Factory was established in 2002, located in Pizhou City, Jiangsu Province, covering

30,000 square meters, has 200 workers with 50.000CBM/year capacity, exports 1000 containers per year

6. ADVANTAGE 1)Professionalmanufacture technology and strong global resource meet your various demand. 2)Perfect and independent inspection system 3)Owner equips very fluent spoken English will further promote strategic partnership building between the two sides. 4)Honest and trustworthy. Responsible until after-sales.

7. MAIN MARKET Europe, America, Australia, Middle East, Asia, and Africa.

8. SERVICE HW has a sales team, docs team, quality inspection team, and logistics team

Mark:

Application

Wood veneer would be widely used as door inserts, floor, wall panels, ceiling panels, privacy screens, architectural millwork, and

furniture inlays, hotels, shopping malls, restaurants, lounges, commercial spaces, chains, offices, expos, columns, furniture, slide door,

interior door, house, bar, etc.

FAQ

Q: What is African teak?

A: African teak (scientific name: Baikiaea Plurijuga) is a hardwood species native to the African savanna. It is also known as Rhodesian teak, Mukusi, or Zambian teak.

Q: How is sliced African teak veneer made?

A: Sliced African teak veneer is made by slicing a log of African teak into thin sheets using a slicing machine. The resulting veneers are then graded based on their quality and sold to customers for various applications.

Q: What are the benefits of using sliced African teak veneer?

A: Sliced African teak veneer has several benefits, including its durability, beauty, versatility, and sustainability. It is also relatively easy to work with, making it a popular choice for both professional woodworkers and DIY enthusiasts.

Q: What are the different applications of sliced African teak veneer?

A: Sliced African teak veneer can be used for a wide range of applications, including furniture, cabinetry, flooring, decorative accents, and more. It is also a popular choice for boatbuilding and outdoor construction due to its resistance to moisture and decay.

Q: How do I care for sliced African teak veneer?

A: To care for sliced African teak veneer, it is recommended to clean it regularly with a soft cloth and mild detergent. Avoid using harsh chemicals or abrasive cleaners that can damage the wood. It is also recommended to avoid exposing the veneer to direct sunlight or extreme temperatures, as this can cause it to fade or warp over time.