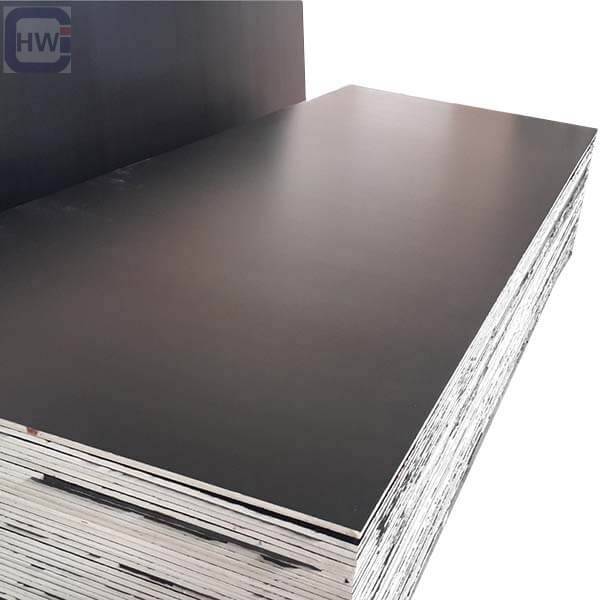

HW Black Oversize Film Faced Plywood For Sale

HW Black Oversize Film-Faced Plywood Feature

1. Oversize: HW Black Oversize Film Faced Plywood is available in large 4′ x 10′ sheets, which makes it an ideal choice for larger projects where fewer seams and joints are desired.

2. Black film coating: The black film coating on both sides of the plywood not only makes it highly durable but also gives it a sleek and modern appearance.

3. Water-resistant: The film coating provides excellent water resistance, which makes HW Black Oversize Film-Faced Plywood suitable for use in wet or humid environments.

4. Chemical-resistant: The plywood is resistant to a wide range of chemicals, which makes it suitable for use in areas where chemicals are present, such as factories, laboratories, and chemical plants.

5. Easy to clean: The smooth surface of the plywood makes it easy to clean, and it can be wiped down with a damp cloth or cleaned with a pressure washer.

6. Versatile: HW Black Oversize Film-Faced Plywood can be used in a variety of applications, including concrete formwork, flooring, walls, and ceilings.

High load-bearing capacity: The plywood has a high load-bearing capacity, which makes it suitable for use in construction and engineering applications.

Plywood, film-faced plywood, also known as clean water template, is produced according to GB 17656-2008. It is made of rotary cut veneers from Chinese poplars and high-quality waterproof glue and is processed by high temperature and high pressure. It can be used repeatedly for more than 10 times, without warping and deformation for its good water resistance character. It can be widely used in various concrete engineering such as high-speed railways, subways, and airport ports, as well as in infrastructure projects such as shear walls, vertical wall panels, bridges, dams and tunnel construction, civil construction, and commercial engineering. It could shorten the construction period: firstly, it is easy to de-mold, only one-seventh time of the steel mold de-molding; secondly, the surface is flat avoiding the secondary plastering process; thirdly, good insulation performance makes winter construction favorable.

Film-faced plywood, shuttering plywood, construction plywood, and concrete plywood, 18mm thickness is very popular, plywood can be made by full poplar core and finger joint core. We use good veneers, so their density is high with strong bearing capacity and long service life.

Parameters of Oversize Film-Faced Plywood

| Place Of Origin | Jiangsu,China (Mainland) |

| Size | 1.small sizes:915x1830mm,610x2500mm 2.standard sizes:1220X2440mm, 1250x2500mm 3.big size:1500x3000mm/1525*3050mm,(accept customization) |

| Thickness | From 12mm to 40mm |

| Material | Peeing veneer;poplar;combi;eucalyptus;birch;pine;meranti; othe hardwood; or finger joint recycled core; |

| Face&back | phenolic paper film;dyspnea;Enso;local;smooth;ultra brighten; antislip(wire mesh,anti-skid) |

| Glue | phenolic formaldehyde adhesive(PF,phenolic WBP glue,phenolic glue) melamine WBP glue(MUF,MF,melamine glue) |

| Emission content of formaldehyde | E0(PF Glue);E1/E2(MUF) |

| Usage | construction;construction formwork;template,mold;shuttering;decking;special packing; Truck Floor, RV Floor etc |

| Layers | finger jointed(5,7ply),9mm(5,7,9ply),12mm(7,9Ply) 15mm(7,9,11ply),18mm(7,9,11,13,15ply) |

| Certificate | CE,CARB,, EPA, FSC,ISO9001 |

| Moisture content | 8%-12% |

Packaging and Containerization of Oversize Film Faced Plywood

Application:

Over-sized Film Faced Plywood used for RV/Truck Floor, Construction, Formwork system, etc.

FAQ

Q: What are the dimensions of HW Black Oversize Film-Faced Plywood?

A: HW Black Oversize Film Faced Plywood is available in large 4′ x 10′ sheets, which are larger than standard plywood sheets. The thickness can vary depending on the specific product and manufacturer.

Q: What is the black film coating made of?

A: The black film coating on HW Black Oversize Film Faced Plywood is typically made of phenolic resin or melamine resin, which makes it highly durable, water-resistant, and chemical-resistant.

Q: Can HW Black Oversize Film-Faced Plywood be used for outdoor projects?

A: While HW Black Oversize Film Faced Plywood is highly water-resistant, it is not recommended for extended outdoor use as exposure to UV light and weather conditions can cause the film to degrade over time. However, it can be used for short-term outdoor projects, such as temporary structures.

Q: How is HW Black Oversize Film-Faced Plywood installed?

A: HW Black Oversize Film Faced Plywood can be installed using standard woodworking tools such as a circular saw, table saw, or jigsaw. It is important to use a sharp blade and take care to avoid splintering or chipping the edges. The plywood can be attached to framing or supports using screws or nails.

Q: Is HW Black Oversize Film-Faced Plywood eco-friendly?

A: The production of HW Black Oversize Film Faced Plywood may not be eco-friendly as it may involve the use of chemicals and other materials that can have negative environmental impacts. However, it is important to check with the specific manufacturer to ensure that their production practices meet your environmental standards.