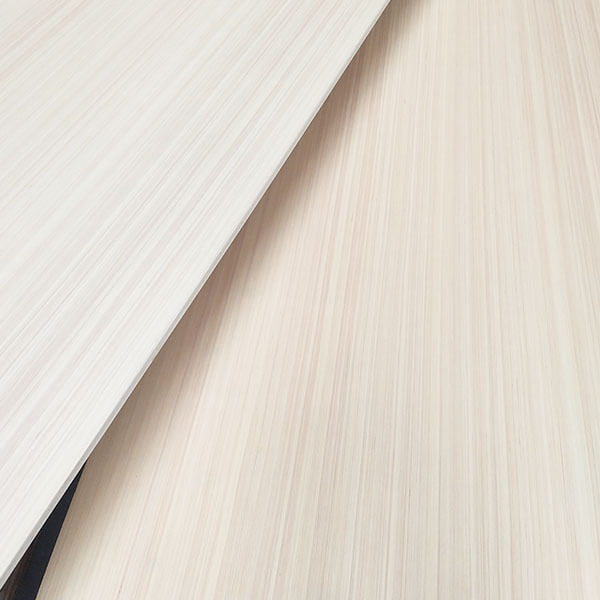

HW 1220x2440mm High-Quality Engineered Veneered Plywood

Product Details

Plywood is comprised of multiple plies of wood veneer giving it high stability, suitable for both indoor and outdoor use. It is usually used for Automotive Interiors, Furniture, Room Decoration, Construction, and Packing.

Below are the advantages, of why customers choose our plywood:

The good veneer price and the poplar core quality are great. could be used for the inner part.

Hard and durable quality, make them long usage life.

Factory quality guarantee, quality problems? contact us.

Well packed, and has good protection while shipping.

High-Quality Engineered Veneered Plywood Feature

1. Durability: Engineered veneered plywood is known for its exceptional durability and strength, making it a popular choice for high-stress applications such as furniture, cabinetry, and flooring.

2. Stability: Veneered plywood is designed to be stable and resistant to warping, shrinking, or swelling, making it an ideal choice for construction and architectural projects.

3. Aesthetics: Veneered plywood can be finished with a variety of stains, paints, and sealants to achieve a desired look and enhance its durability. It can also mimic the look of solid wood, making it an attractive option for a wide range of interior and exterior applications.

4. Sustainability: Engineered veneered plywood is made using sustainable materials, such as fast-growing plantation species, making it an eco-friendly option.

5. Cost-effective: Compared to solid wood, veneered plywood is generally more affordable, making it a practical choice for large-scale construction or manufacturing projects.

6. Versatility: Veneered plywood can be cut and shaped to fit a wide range of applications, making it a versatile material for both interior and exterior use.

Face Veneers

Bintangor

natural-birch-plywood

poplar-plywood-china-supplier

Product Parameters

| Product Name | HW 5-30MM Commercial Plywood for Furniture | ||

| Size | 1220x2440mm/1250x2500mm/ or as the client’s requirement | ||

| Thickness | 5-30mm | ||

| Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | ||

| Face/Back | E-Wood, Okoume, Ilomba, Poplar, Birch, Bintangor, Hardwood, Pine, Pencil Cedar, Keruing, Agathis, Meranti, etc. | ||

| Core | Poplar, hardwood, eucalyptus, Okoume, birch, pine, combi, etc. | ||

| Joint Way of The Core | Overlap joint, end joint, scarf joint, or finger joint | ||

| Glue | E0, E1, E2, MR, Melamine or WBP | ||

| Grade | B/BB,BB/BB,BB/CC,DBB/CC; ect | ||

| Density | 520~700kg/m3 | ||

| Technical Parameters | Moisture Content | <12% | |

| Water Absorption | ≤10% | ||

| Modulus of Elasticity | ≥5000Mpa | ||

| Static Bending Strength | ≥30Mpa | ||

| Surface Bonding Strength | ≥1.60Mpa | ||

| Internal Bonding Strength | ≥0.90Mpa | ||

| Screw Holding Ability | Face | ≥1900N | |

| Edge | ≥1200N | ||

| Usage & Performance | Plywood is widely used for Automotive Interiors, furniture, decoration, construction, and packing. With good properties, such as easy fabricability, high bending strength, strong screw-holding ability, heat resistance, anti-static, long-lasting, and no seasonal effect. | ||

| MOQ | 1×20’FCL | ||

| Supply Ability | 5000cbm/month | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 20 days after receiving the deposit or original L/C at sight | ||

| Certification | CE, FSC, EUTR, CARB,EPA, JAS, ISO | ||

| Mark | EV veneers also named reconstituted veneers laminated plywood is one of our best-selling furniture grade of boards. We usually recommend customers for the Poplar Core, combi core, and eucalyptus core strive for high-end quality products. surface species can be a lot of different series, like oak, teak, poplar, cherry, and so on, and we are working with several big mills of recon veneers producer for multichoice. and this product is ideal for the furniture grade and countertop material first choice. | ||

Delivery Instructions

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization

FAQ

Q: What is engineered veneered plywood?

A: Engineered veneered plywood is a type of wood product that is made by bonding together several layers of thin wood veneers using a strong adhesive. This process creates a strong and durable sheet that is suitable for a wide range of applications.

Q: What are the advantages of using engineered veneered plywood?

A: There are several advantages to using engineered veneered plywood. It is more affordable than solid wood, it is sustainable, and it is durable and stable. Additionally, veneered plywood can be finished with a variety of stains and paints to create a desired look.

Q: What applications is engineered veneered plywood suitable for?

A: Engineered veneered plywood is suitable for a wide range of applications, including furniture, cabinetry, flooring, wall and ceiling panels, partitions, and decorative features. It is also commonly used in construction and architectural projects.

Q: How is high-quality engineered veneered plywood made?

A: High-quality engineered veneered plywood is made using high-grade hardwood veneers and adhesives that are specifically designed for plywood production. The veneers are carefully selected for quality and consistency before being bonded together to form a strong and durable sheet.

Q: Is engineered veneered plywood eco-friendly?

A: Yes, engineered veneered plywood can be an eco-friendly option because it is made using fast-growing plantation species that are sustainable and renewable. Additionally, the manufacturing process for veneered plywood produces less waste than traditional solid wood production.