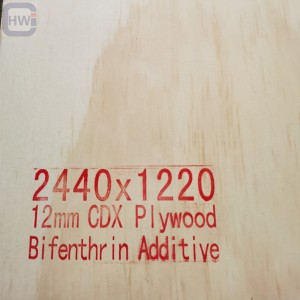

CDX Structural Plywood

Structural Plywood has been manufactured at our plant in China, for in excess of 15 years and has been used successfully in Asia, Australia and New Zealand.

Structual plywood for strong, stable. Structural Plywood has been manufactured at our plant in China, for in excess of 15 years and has been used successfully in Asia, Australia and New Zealand.

For domestic and light commercial structural and decorative applications manufactures structural plywood in a range of widths, lengths, thicknesses and grades to AS/NZS2269 from Newzealand and Russia-sourced plantation Radiata Pine and Larch. Products are certified by Certmark.

Structural plywood is for use in all permanent structural and engineered applications.

A Bond is durable and permanent under conditions of full weather exposure and long-term stress.

Structural plywood should be preservative-treated to ensure it lasts its full-service life as it is manufactured from a range of hardwood and softwood timber species.

For termite and rot resistance, plywood can be treated to H2, H3 or H4 standards. Or for a lower-cost alternative can be manufactured with a bifenthrin glue line additive which provides termite resistance but is only suitable for use south of the tropic of Capricorn.

Testing and certification are carried out by Certemark International (CMI) and DNV.

Formply provides assurance of quality and consistency.

Introduction

CDX Structural Plywood is a type of plywood that is commonly used in construction projects throughout North America. The name “CDX” refers to the quality of the plywood, with “C” representing the front surface of the plywood and “D” representing the back surface. The “X” indicates that the plywood is intended for exterior use.

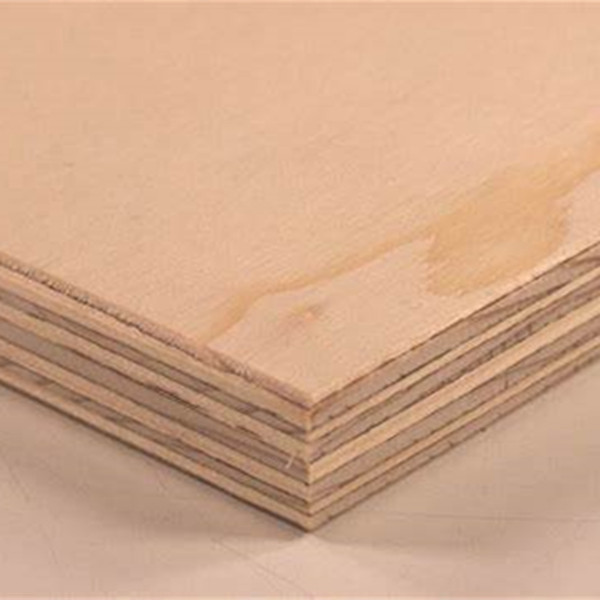

CDX Structural Plywood is made from multiple layers of wood veneer that are glued together with each layer’s grain running perpendicular to the previous layer. This cross-grain construction provides strength and stability to the plywood, making it suitable for use in load-bearing applications. The plywood is typically made from softwood species such as pine, fir, or spruce.

CDX Structural Plywood is designed to be strong and durable, making it suitable for use in load-bearing applications such as walls, roofs, and subfloors. It is also treated to be resistant to moisture and rot, making it suitable for use in humid or damp environments. CDX Structural Plywood is available in various thicknesses, ranging from 1/4 inch to 1 inch or more, and is widely available from lumber and building supply stores throughout North America.

Features

1. Construction: CDX Structural Plywood is made from multiple layers of wood veneer that are glued together with each layer’s grain running perpendicular to the previous layer. This cross-grain construction provides strength and stability to the plywood.

2. Strength: CDX Structural Plywood is designed to be strong and durable, making it suitable for use in load-bearing applications.

3. Moisture resistance: While not completely waterproof, CDX Structural Plywood is treated to be resistant to moisture and rot, making it suitable for use in humid or damp environments.

4. Thickness: CDX Structural Plywood is available in various thicknesses, ranging from 1/4 inch to 1 inch or more.

5. Uses: CDX Structural Plywood is commonly used in residential and commercial construction projects for load-bearing applications such as walls, roofs, and subfloors.

6. Availability: CDX Structural Plywood is widely available from lumber and building supply stores throughout the United States.

| Normal Thickness | Sheet Size (mm) | Grade | Density (kg/cm) | Face and back | Core Materials | Moisture | Glue | Thickness Tolerance | Packing Unit ( sheets ) |

| 1/8inch (2.7-4.0mm) | 1200×2400 | A/B | 580 | Larch/ Pine | Larch/hardwood/ pine | 8-14 % | Waterproof Super E0 | +/-0.2mm | 150 / 400 |

| 1/2inch (12-12.7mm) | 1200×2400 | B/C | 550 | Larch/ Pine | Larch/hardwood/ pine | 8-14 % | +/-0.5mm | 70 / 90 | |

| 5/8inch (15-16mm) | 1200×2400 | C/C | 530 | Larch/ Pine | Larch/hardwood/ pine | 8-14 % | +/-0.5mm | 60 / 70 | |

| 3/4inch (18-19mm) | 1200×2400 | C/D | 520 | Larch/ Pine | Larch/hardwood/ pine | 8-14 % | +/-0.5mm | 50 / 60 |

Advantages of HW Structural Plywood

Manufactured from sustainably-grown plantation pine and Larch

Available in B, C and D surface appearance grades

Sheet thicknesses: 3 to 40mm

Sheet dimensions: 2400/1800 × 1200mm

Supplied in F8/F27 stress grade

Uncoated high-appearance surface suitable for clear, stain and paint finishes

Contains a second void-free layer under the surface veneer increasing protection

from moisture bubbles and high-point loads

Low formaldehyde emission (E0)

Application of HW Structural Plywood

Packaging and Containerization of HW Structural Plywood

FAQ

Q: What is the difference between CDX and ACX plywood?

A: CDX plywood is designed for exterior use and has a rough, unfinished appearance. ACX plywood is also designed for exterior use but has a smoother finish on both sides.

Q: What is CDX plywood used for?

A: CDX plywood is commonly used in construction projects for load-bearing applications such as walls, roofs, and subfloors.

Q: Is CDX plywood waterproof?

A: While not completely waterproof, CDX plywood is treated to be resistant to moisture and rot, making it suitable for use in humid or damp environments.

Q: What sizes does CDX plywood come in?

A: CDX plywood is available in various thicknesses, ranging from 1/4 inch to 1 inch or more, and typically comes in 4′ x 8′ sheets.

Q: What type of wood is used to make CDX plywood?

A: CDX plywood is typically made from softwood species such as pine, fir, or spruce.