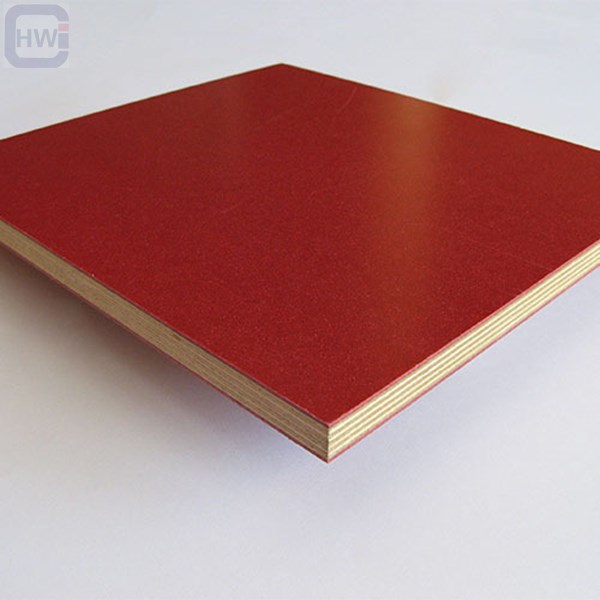

Red Film Faced Plywood

Film-Faced Plywood:

Film-faced plywood is thin, water- and corrosion-resistant, easily combines with other materials, and is simple to cut and clean. The edges of the film-faced plywood are treated with waterproof paint to greatly increase its resistance to wear and water. Open locations can use it for building and construction because of its easy-to-handle surface and durability.

To ensure hardness and damage resistance, high-quality imported films are applied to the film-faced plywood.

The film-faced plywood has a sanitary surface that is stain- and detergent-resistant.

It works well in situations when there is a sudden drop in temperature, moisture intrusion, detergent cleaning, and termite protection.

We have two varieties of plywood with a film face. First, there is birch film-faced plywood, which is among the highest-quality plywood in the world and is very water-resistant, easy to clean and cut. Plywood with a poplar film face is the second. Compared to plywood with a birch film face, this type of plywood is lighter and softer and is also easier to clean and cut.

Red Film-Faced Plywood Feature

1. Durable: The red phenolic film provides extra durability to the plywood, making it resistant to water, weather, and chemicals.

2. High Strength: The plywood is made from high-quality hardwood veneers that give it excellent strength and load-bearing capacity, making it ideal for use in heavy-duty construction applications.

3. Smooth Finish: The phenolic film provides a smooth and glossy finish to the plywood, giving it an aesthetically pleasing appearance.

4. Easy to Clean: The film surface is easy to clean, making it ideal for use in applications where cleanliness is important, such as in hospitals, schools, and other public buildings.

5. Cost-effective: Red Film Faced Plywood is a cost-effective building material that provides excellent value for money due to its durability and long life.

6. Versatile: The plywood is suitable for a wide range of applications such as concrete formwork, wall paneling, flooring, and roofing, making it a versatile construction material.

7. Environmentally Friendly: Red Film Faced Plywood is made from sustainably sourced hardwood, making it an environmentally friendly choice for construction projects.

Specification of Film-Faced Plywood:

1). Film color:

Red, Brown, Black, or others

Brown or black film is the most often used type of film. Plywood with a brown film face is often of higher grade in China than plywood with a black film face. It’s not always true, though. Similar to brown film-faced plywood, some black film-faced plywood is of the same excellent quality. An experienced salesperson will be able to determine what the actual quality you require when you make an inquiry.

2). Quality of Film :

There are two categories of films in China: domestic and foreign films. Chinese production companies’ films are considered local films. Films produced by foreign studios, such as Dynea, are considered imported. China’s top film brand is Dynea Film. Thus, we will utilize Dynea film if you need the best film for your plywood.

3). Core:

Poplar, Hardwood, Eucalyptus, Birch

Poplar film-faced plywood, which is of excellent quality and competitive pricing, makes over 70% of the film-faced plywood we sell. We will utilize hardwood or eucalyptus veneers if you require plywood with a film front on hardwood. Hardwood film-faced plywood is an excellent option if you’re looking for film-faced plywood for building bridges or tall buildings since, as its name implies, it’s quite durable. We can provide sturdy, robust plywood with a birch film face.

4). Glue:

Phenolic-WBP; Melamine-WBP; MR

5). Size:

1220X2440mm, 1250X2500mm, or 4′ x 8′, standard size, large size, big size, special size

We generate sizes based on the specifications provided by clients. Maximum length is 6000mm, and maximum width is 2000mm.

6). Thickness:

4mm-30mm (4mm / 6mm / 9mm / 12mm / 15mm / 18mm / 21mm-50mm )

We supply very thin film-faced plywood of 4mm and the thickest plywood of up to 50mm. This is our advantage.

7) Edge:

Sealed by water-proof paint

8) Usage :

Formwork panel for construction; stairs; automobile trailers; container floor and wall; automotive engineering floor and side walls, and

other special applications etc.

9 ) Mark:

It also enjoys the same properties as film-faced plywood in regards to moisture resistance/proof (depending on the bonding glue type).

Contact us if you need more info.

Delivery Instructions of Film-Faced Plywood:

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization of Film-Faced Plywood:

Application of Film-Faced Plywood:

Film-faced plywood can also be used to build sliding doors, advertising boards, playground equipment, floors for sports arenas, smooth concrete casts, scaffolding, hoardings and fencings, packing, and in internal & external design and paneling.

1) Construction industry: Shuttering Film Faced Plywood, Concrete Formwork, Shuttering Concrete Formwork, Formwork Plywood

Film-faced plywood is mainly used for construction. So film-faced plywood is also called shuttering film-faced plywood, concrete form, or shuttering concrete form. Because of this end use, customers usually want WBP film-faced plywood, which is more suitable to be used as shuttering for big projects. However, some customers require MR film-faced plywood, which is to be used as shuttering for ordinary projects.

2) Film Anti-Slip Faced Plywood is used to provide work platforms and floors for automobiles.

According to the types of face/back, film-faced plywood can be divided into smooth film-faced plywood and anti-slip film-faced plywood. Anti-slip film-faced plywood is usually used as the flooring material for vehicles, trucks, and platforms.

3) Film-faced plywood can be used for shelves and furniture, too.

Compared with wood veneer-faced plywood, film-faced plywood is more durable and has more wear-resistant surfaces. So it can be used for making durable furniture and shelves.

FAQ

Q: What is the thickness of Red Film Faced Plywood?

A: Red Film Faced Plywood is available in different thicknesses ranging from 6mm to 21mm, depending on the specific requirements of the project.

Q: Can Red Film-Faced Plywood be used for outdoor applications?

A: Yes, Red Film Faced Plywood is designed to be weather-resistant and can be used for outdoor applications such as roofing, flooring, and wall paneling.

Q: What is the maximum load capacity of Red Film Faced Plywood?

A: The maximum load capacity of Red Film Faced Plywood varies depending on the thickness of the plywood and the specific application. Generally, it has a high load-bearing capacity and is suitable for heavy-duty construction applications.

Q: Can Red Film Faced Plywood be reused after being used for concrete formwork?

A: Yes, Red Film Faced Plywood can be reused multiple times after being used for concrete formwork, provided that it is properly maintained and cared for.

Q: Is Red Film Faced Plywood environmentally friendly?

A: Red Film Faced Plywood is made from sustainably sourced hardwood and is considered to be an environmentally friendly building material. However, it is important to ensure that the plywood is sourced from reputable suppliers who follow sustainable forestry practices.