Ultralight Birch Poplar Plywood Panels combine the strength of birch and the lightweight nature of poplar, offering a superior material choice for modern projects. In the realms of construction and design, these ultralight panels stand out for their ease of handling, adaptability, and enhanced aesthetic appeal, positioning them as a preferred choice for innovators and visionaries alike.

Birch and Poplar Plywood: Versatile Wood Composites

Origin and Properties

Birch plywood is derived from the hardy birch tree, known for its fine grain and durability, while poplar plywood is sourced from the fast-growing poplar tree with a coarser grain. Both types are manufactured by layering thin sheets of wood veneer, with each layer glued at right angles to the previous one. This cross-grain construction imparts exceptional strength and stability to these plywood varieties.

Advantage of Lightness and Strength Combination

One remarkable characteristic of both birch and poplar plywood is their exceptional strength-to-weight ratio. They are renowned for being lightweight yet robust, making them ideal for various applications that require structural integrity without adding excessive weight. This unique combination of lightness and strength sets them apart from other plywood options, making them preferred choices for many projects.

Common Applications and Uses

Birch and poplar plywood find extensive use in diverse applications. They are commonly employed in furniture manufacturing, cabinetry, and interior paneling due to their attractive appearance and ease of machining. Moreover, their strength makes them suitable for structural components in construction, such as wall sheathing and subflooring. These plywood varieties are also popular in boat-building, packaging, and crafting, showcasing their versatility across numerous industries.

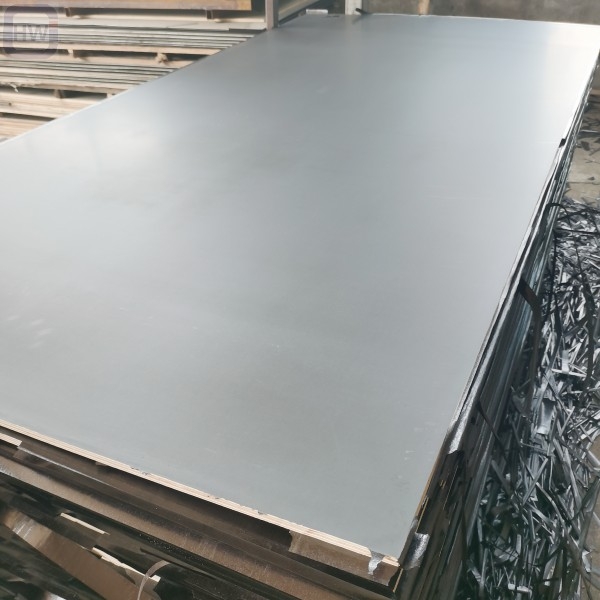

Film Faced Birch Plywood: A Durable Building Essential

Explanation of Film Facing

Film faced birch plywood is a specialized plywood variety designed for enhanced durability and resistance to external elements. Its unique feature is the application of a phenolic or melamine film on one or both sides of the plywood sheets. This film, usually dark brown or black, creates a robust and smooth surface that offers several advantages.

Benefits of Using Film Faced Birch Plywood

- Moisture Resistance: The film acts as a protective barrier, making the plywood highly resistant to moisture, water, and weathering. This makes it ideal for outdoor and wet environments, such as concrete formwork in construction.

- Improved Appearance: The smooth, even surface provided by the film facing gives the plywood a clean and attractive appearance. This quality is especially valuable when exposed surfaces need to look professional and aesthetically pleasing.

- Extended Lifespan and Durability: Film faced birch plywood is exceptionally durable, with the film layer adding an extra level of protection against wear and tear. This longevity reduces the need for frequent replacements, saving time and costs.

Popular Uses in Construction, Cabinetry, and More

Film faced birch plywood finds wide-ranging applications across various industries. In construction, it is a preferred choice for forming concrete structures, including walls, slabs, and pillars. Its moisture resistance ensures the integrity of the formwork and minimizes concrete surface defects.

Additionally, this plywood type is used in cabinetry, where its durability and sleek appearance enhance the quality of finished products. It is also suitable for applications in transportation, shipbuilding, and agriculture due to its resilience and moisture-resistant properties.

Phenolic Faced Birch Plywood: Strength and Durability Unleashed

Understanding Phenolic Resins and Their Application on Plywood

Phenolic faced birch plywood is fortified with a layer of phenolic resin-impregnated paper or film on its surface. Phenolic resins are synthetic thermosetting polymers known for their exceptional durability and resistance. This layer is bonded to the plywood using heat and pressure, creating a formidable composite material.

Advantages of Phenolic-Faced Plywood

- Superior Surface Hardness: The phenolic facing imparts remarkable surface hardness to the plywood, making it highly resistant to dents, scratches, and impact. This quality ensures a long-lasting and robust surface.

- Resistance to Chemicals and Wear: Phenolic-faced plywood exhibits outstanding resistance to a wide range of chemicals, including solvents and acids. It can withstand exposure to harsh substances without deteriorating, making it suitable for demanding environments.

- Ideal for High-Traffic Areas: Its durability and resistance to wear make phenolic-faced plywood ideal for high-traffic areas where constant use and heavy loads are expected. It maintains its integrity even under rigorous conditions.

Applications in Heavy-Duty Platforms, Transport, and Industrial Settings:

Phenolic faced birch plywood is a preferred choice in applications that demand uncompromising strength and durability. It is commonly used in heavy-duty platforms and scaffolding systems, ensuring safety and stability in construction and maintenance tasks. Additionally, it is employed in the transport industry for trailer floors, truck beds, and container linings, thanks to its ability to withstand heavy cargo and rigorous loading and unloading processes. In industrial settings, it finds utility in the construction of workbenches, storage units, and equipment surfaces that must endure intense use.

Film Faced vs. Phenolic Faced Plywood: Making the Right Choice

A Side-by-Side Look at Their Differences

- Film Faced Plywood:

- Film faced plywood features a film layer typically made of phenolic or melamine on one or both sides.

- It is primarily designed for moisture resistance, making it ideal for concrete formwork and outdoor applications.

- The film can vary in color, with dark brown or black being common choices.

- It offers a smooth and visually appealing surface.

- Phenolic Faced Plywood:

- Phenolic faced plywood includes a layer of phenolic resin-impregnated paper or film on the surface.

- It is prized for its exceptional durability and resistance to wear, chemicals, and impact.

- The surface tends to be harder and more abrasion-resistant than standard film faced plywood.

- Phenolic facing often appears in a variety of colors, offering aesthetic options.

Factors to Consider When Choosing Between the Two

- Project Requirements:

- Film faced plywood is ideal for projects requiring moisture resistance, such as concrete formwork.

- Phenolic faced plywood excels in high-traffic areas and applications where surface durability is critical.

- Cost Implications:

- Film faced plywood is generally more cost-effective due to its primary focus on moisture resistance.

- Phenolic faced plywood may be costlier but offers superior surface hardness and longevity.

- Aesthetic Preferences:

- Film faced plywood provides a smooth surface and limited aesthetic choices.

- Phenolic faced plywood offers a wider variety of colors and a harder surface, making it suitable for projects with specific design considerations.

CONCLUSION

In the realm of high-quality ultralight plywood, the film and phenolic-faced variants in birch and poplar stand as exceptional choices. Film-faced plywood offers moisture resistance and a smooth finish, ideal for various applications, while phenolic-faced plywood showcases unmatched durability and surface hardness, perfect for demanding environments. The choice between the two ultimately depends on specific project needs, budget, and aesthetic preferences. Regardless of your selection, these plywood options represent the pinnacle of lightweight strength, catering to a wide array of industries, from construction to woodworking.

Post time: 17 10 月, 2023