The introduction of structural Plywood:

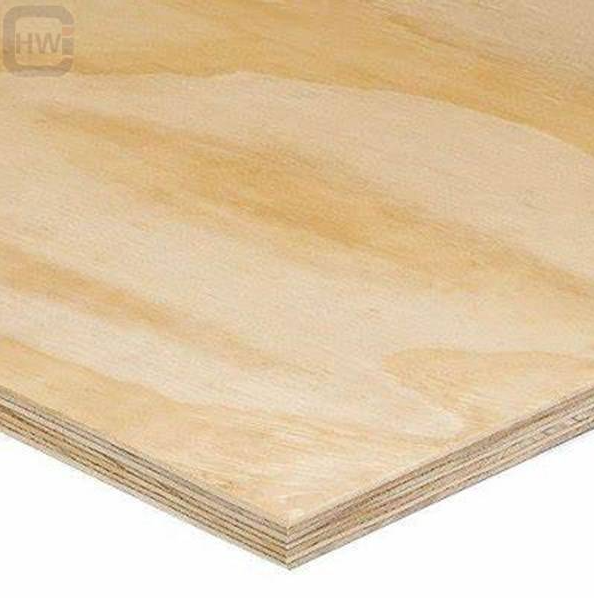

- A kind called HW Structural Plywood is created and produced for load-bearing applications in the building sector. It is created with each layer’s grain running perpendicular to the layer behind it using premium hardwood species to provide it strength and stability. Structural Plywood, a fundamental and extremely versatile building material, has completely transformed modern construction techniques.

- This Plywood harnesses the strength and resilience of wood, engineered through a precise layering process to provide a flexible option for various construction applications. This engineered wood product is painstakingly made by combining layers of thin wood veneers in a purposeful cross-grain arrangement, creating a composite material that combines the greatest qualities of both natural wood and cutting-edge production processes.

- Due to its distinctive combination of qualities, structural Plywood is essential to modern construction projects. Its excellent strength-to-weight ratio makes it a prime alternative for structural sheathing, giving walls, floors, and roofs essential lateral support and stability. Due to its dimensional stability and resistance to warping, it is a great option for underlayment and subflooring, providing a stable base for various flooring materials.

Everything You Need to Know About Plywood: Understanding Plywood:

A panel product called Plywood is created by adhering together thin layers of wood veneers, sometimes called plies or layers, with the grains of the veneers alternating at right angles. A sturdy and stable sheet is created when the layers are adhered together using adhesive under intense pressure and heat. The type of wood used, the glue, the thickness of the veneer, and the production method are only a few examples of the variables that affect Plywood’s quality and performance.

The Structural Properties and Applications of Plywood in Construction:

Plywood is a flexible and often used engineered wood product. Because of its special structural qualities and benefits, it has found several uses in the building sector. It is created by stacking thin wood veneer sheets, also known as plies or layers, with the wood grain aligned perpendicular to surrounding layers. Then, under intense pressure and heat, adhesives join these layers together. The qualities that plywood gains from this building process make it ideal for use in various construction applications.

Structural characteristics:

- Strength and Durability:

Structural Plywood has high strength and rigidity due to its layered construction and cross-grain arrangement. It spreads loads over several layers, improving its ability to support weights and strengthening its resistance to bending and deformation.

- Dimensional stability:

The alternating grain orientation of neighboring layers prevents wood from expanding and contracting due to variations in temperature and humidity. Plywood is more dimensionally stable and less prone to warping and splitting than solid wood.

- Uniformity:

Plywood produced by established standards has constant mechanical characteristics, thickness, and density. Because of its homogeneity, it is simpler to forecast and manage its performance across various applications.

- Impact Resistance:

The layered construction of Plywood helps it withstand impact loads. This quality is especially useful when the material is subjected to abrupt stresses or impacts.

- Workability:

This Plywood is easily cut, shaped, and drilled using typical woodworking equipment. It is useful for ornamental applications since it also accommodates a range of treatments and coatings.

Construction-related applications:

- Plywood is used in walls, roofs, and floors as structural sheathing. In addition to helping to disperse loads brought on by wind and seismic forces, it gives structures lateral stability.

- Plywood is a sturdy foundation for flooring materials, including hardwood, laminate, and tile. See also subflooring and underlayment. Its level surface is a smooth base for installing flooring and prevents unevenness.

- Roof decking made of Plywood may support roofing materials like metal panels or shingles. Its rigidity and strength help the roof structure’s overall stability.

- For casting concrete constructions like columns, walls, and beams, Plywood is frequently used as the formwork. After the concrete has dried, it produces a smooth surface finish and is simple to remove.

- Plywood is a popular material for cabinets, furniture, and interior fittings because of its sturdiness, use, and possibility for attractive design.

- Some plywood varieties, such as exterior-grade Plywood, may coat structures in a beautiful and weatherproof material.

- Plywood may be used to make beautiful wall panels, ceilings, and partitions, giving interior spaces a creative flair.

- Due to its simplicity of installation and disassembly, Plywood is frequently used to build temporary structures, including stages, booths, and event structures.

The Features of XUZHOU CHANGYU WOOD Structural Plywood:

- Because of its strength and durability, HW Structural Plywood is appropriate for load-bearing applications in the construction sector. Its architecture, in which the grain runs perpendicular to that of the preceding layer, offers stability and strength.

- A flexible building material, Plywood may be utilized for various construction purposes, including walls, floors, roofs, and structural framing. It is suited for small and big building projects since it is offered in various thicknesses and sizes.

- This Plywood is produced by high-quality standards and is intended to endure inclement weather. It is perfect for outdoor building projects since it is resistant to dampness, decay, and pests.

- It is created with each layer’s grain running perpendicular to the layer behind it using premium hardwood species to provide it strength and stability.

Conclusion:

Sheathing Plywood, sometimes called structural Plywood, is a multipurpose and dependable building material that has grown in favor of the building sector. To make a sturdy and long-lasting panel, many layers of wood veneer are bonded together to form this Plywood. The strength of this Plywood is one of the key factors in its widespread use. The worlds of building and woodworking benefit greatly from the versatility and need of Plywood. It is a great option for various projects because of its strength, longevity, and wide range of uses. It is vital to consider a recognized producer while looking for Plywood, such as XUZHOU CHANGYU WOOD, renowned for its dedication to quality, sustainability, and customer happiness.

Post time: 28 8 月, 2023