Anti-Slip Red Film Faced Plywood

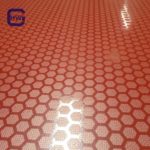

Hexagonal Anti-slip Film Faced Plywood / Red Anti-slip Film Faced Plywood

There is a new pattern of anti-slip film-faced plywood called Hexagonal Anti-slip Film Faced Plywood, which is different from the pattern of wire-mesh anti-slip film-faced plywood.

- Face and Back:

Hexagonal Pattern Wire Mesh Grey / Brown / Black Phenolic Resin Film 220 g/m2 or other colors upon request

Domestic black /brown wire mesh/smooth film, Imported wire mesh/smooth film

- Species Of Core Veneers:

Russian Birch Ply / Baltic Birch Ply / Eucalyptus Ply / Poplar Ply / Combi Ply

- Glue:

Phenolic-WBP, Melamine-WBP

- Sizes:

1200mm X 2440mm, 1500mm X 3000mm, or upon request

Width: 1200mm, 1220mm, 1250mm, 1500mm, 1525mm, 1800mm, 1830mm, 2000mm, or another width no more than 2000mm;

Length: 2400mm, 2440mm, 2500mm, 3000mm, 3050mm, 3600mm, 3660mm, 4270mm, 4575mm, 4880mm, 5185mm or another length no more than 6000mm;

- Thickness:

9mm / 12mm / 15mm / 18mm / 21mm / 24mm / 27mm (1/8″, 1/4″, 3/8″, 1/2″, 5/8″, 3/4″, 1″, 1-1/8″ 1-1/4″, 1-1/2″ ) or other thickness no more than 50mm

- Edge:

Sealed by water-proof paint

- Usage :

Construction formwork panel/ Stairs/car trailers/ Container floor and wall/automotive engineering floor and side walls and other special applications etc.

- Mark:

Our HW product series is antislip/nonskid film-faced plywood with 1 side wire mesh film and the other side smooth phenolic resin coating/film. The application of this our Meshplex is mainly: antislip floor and wall in car trailer/container body and also some other special occasions like stairs etc. As long as you have anti-slip demand, you can consider our Meshplex.Except for anti-slip function,

Meshplex is also a strong panel(especially for flooring purposes).

It also enjoys the same properties as film-faced plywood in regards to moisture resistance/proof (depending on the bonding glue type).

Contact us if you need more info.

Advantages of Hexagonal Anti-slip Film-Faced Plywood:

1. The phenolic glue of the film-faced plywood can smooth the surface of concrete; If one side is anti-slip, the Hexagonal / Mesh surface provides anti-slip protection

2. High Wear-Resistant, Anti-Cracking, Alkaline-Resistant, Anti-Abrasive, Anti-erosive;

3. Resistant to the effect of various environments, including chemicals, Resistance to temperature variation -40 to +50 °C

4. The water-proof coating extends the working life of the concrete;

5. There is no color contamination between the concrete and the concrete shuttering plywood;

6. Low levels of aldehyde, phenol, and other toxic emissions;

7. The product can be cut to a small size to use again if it is cut, please spray waterproof paint on the edges which have been cut;

8. Birch core, Combi core plywood is more firmly than poplar core, and the best core is Birch.

Features & Advantages of our Anti-slip Film Faced Plywood:

1. Slip-resistant surface: The textured surface of the plywood provides excellent traction, even in wet or slippery conditions, helping to prevent accidents.

2. Moisture resistance: The phenolic resin-impregnated film on both sides of the plywood makes it resistant to moisture and water damage, making it ideal for use in outdoor applications or areas with high humidity.

3. Chemical resistance: The plywood is also resistant to chemicals, making it suitable for use in industrial applications where exposure to harsh chemicals is common.

4. Durability: The hardwood plywood core and high-density overlay make the plywood sturdy and resistant to wear and tear, ensuring it can withstand heavy use and last for a long time.

5. Cost-effective: Anti-slip red film-faced plywood is a cost-effective solution for construction projects, as it can be used in place of other more expensive materials without sacrificing performance or durability.

Our factory has produced anti-slip film-faced plywood for over 10 years. Experienced workers and Fine Management lead to premium quality for the global market.

Delivery Instructions of Hexagonal Anti-slip Film-Faced Plywood:

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization of Hexagonal Anti-slip Film-Faced Plywood:

Application of Hexagonal Anti-slip Film-Faced Plywood:

1. Flooring: Hexagonal anti-slip film-faced plywood is commonly used as a flooring material in areas where slip resistance is critical, such as kitchens, bathrooms, and outdoor decks. The plywood’s textured surface provides excellent traction, even in wet or slippery conditions, helping to prevent accidents.

2. Scaffolding: Hexagonal anti-slip film-faced plywood is also commonly used in scaffolding applications, as it provides a secure and slip-resistant surface for workers to stand on while they perform their tasks. Its durability and resistance to moisture make it ideal for use in outdoor construction sites.

3. Truck and trailer beds: Hexagonal anti-slip film-faced plywood can also be used to line the beds of trucks and trailers, providing a durable and slip-resistant surface for transporting goods.

4. Industrial platforms: Hexagonal anti-slip film-faced plywood is a popular choice for use in industrial platforms, where exposure to harsh chemicals and other hazardous materials is common. It’s chemical resistance and slip-resistant surface make it ideal for use in these applications.

Our Anti-Slip/Skid Film Faced Plywood widely use for vehicle floors. flight cases, ship decking, transport platforms, etc.

FAQ

Q: What is anti-slip red film-faced plywood?

A: Anti-slip red film-faced plywood is a type of construction material that has a textured surface to provide traction and prevent slips. It is made by bonding a high-density overlay (HDO) with a phenolic resin-impregnated film to both sides of a hardwood plywood core.

Q: What are the benefits of using anti-slip red film-faced plywood?

A: The benefits of using anti-slip red film-faced plywood include slip resistance, moisture resistance, chemical resistance, durability, and cost-effectiveness. It is a versatile and reliable construction material that is well-suited for a wide range of applications.

Q: Where can anti-slip red film-faced plywood be used?

A: Anti-slip red film-faced plywood can be used in a variety of applications, such as scaffolding, flooring, truck and trailer beds, and industrial platforms. It is particularly useful in areas where moisture or liquids are present, as it helps to prevent accidents by providing a secure footing for workers and equipment.

Q: How is anti-slip red film-faced plywood installed?

A: Anti-slip red film-faced plywood can be installed using standard construction techniques. It can be cut to size using a saw, and fastened to a subfloor using screws or nails.

Q: What maintenance is required for anti-slip red film-faced plywood?

A: Anti-slip red film-faced plywood requires minimal maintenance. It should be kept clean and free from debris to prevent slips and falls, and any spills or stains should be cleaned up promptly to prevent damage to the surface.